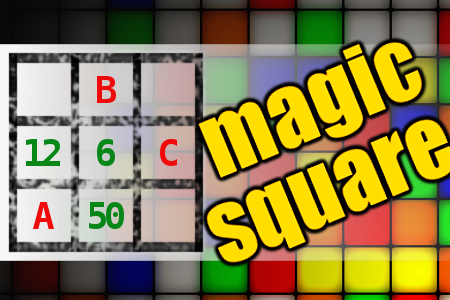

MAGIC SQUARE: Calculate A+B*C

The aim is to place the some numbers from the list (3, 5, 6, 10, 12, 13, 48, 49, 50, 51, 54) into the empty squares and squares marked with A, B an C. Sum of each row and column should be equal. All the numbers of the magic square must be different. Find values for A, B, and C. Solution is A+B*C.Correct answers: 3

#brainteasers #math #magicsquare

Silence

After my husband and I had a huge argument, we ended up not talking to each other for days.

Finally, on the third day, he asked where one of his shirts was.

"Oh," I said, "So now you're speaking to me."

He looked confused,

"What are you talking about?"

"Haven't you noticed I haven't spoken to you for three days?" I challenged.

"No," he said, "I just thought we were getting along."